Prefabricated Steel Structure Warehouse Building Construction Prefab Metal Workshop

Product Specifications

| Attribute |

Value |

| Connection |

Bolt Connection and Welded Connection |

| Dimension |

Customized |

| Forming |

Steel Structure |

| Lifespan |

More than 50 Years |

| Shot Blasting Level |

Sa 2.5 |

| Carbon Structural Steel |

Q355 |

| Surface Treatment |

Painting or Hot-DIP Galvanized |

| Production Capacity |

50000 Square Meter Per Month |

| Columns & Beams |

H-Section Steel |

| Raw Steel Material |

Q235B, Q355b, ASTM A36 |

Applications

Steel Workshop, Steel Structure Platform, Steel Fabricated House, Structural Roofing, Frame Part, Steel Walkway and Floor, Steel Structure Bridge

Project Description

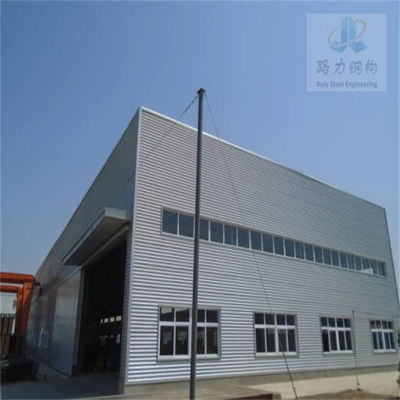

Prefabricated Steel Frame Buildings / Metal Building Frame Structure Warehouse. This steel structure building is used as a car shop with a construction floor area of about 3200 square meters. We provide welded steel beam & column, crane, steel cladding sheet, purlin, windows and doors, and other accessories.

Main Components

Main steel frame structure

Laying purlin

H section steel column

Technical Parameters

| Component |

Specification |

| Main structure |

H section steel Q345, alkyd painting, two primary painting, two finish painting |

| Roof purlin |

XZ160*60*20*2.5, galvanized |

| Wall purlin |

XZ160*60*20*2.5, galvanized |

| Intensive bolt |

Grade 10.9 |

| Roof panel |

Corrugated steel plate or sandwich panel (EPS/fiber glass/rock wool/PU) |

| Wall panel |

Corrugated steel plate or sandwich panel (EPS/fiber glass/rock wool/PU) |

Installation Process

1. We provide construction drawings before installation

2. Our engineer provides on-site guidance for installation

On-site installation guidance

Why Choose Our Steel Structures?

- Low cost - Professional design reduces construction time and material usage

- Environmental protection - Specialized cladding materials provide excellent acoustic and insulation performance

- Recyclable materials - All raw materials can be recycled

- 50+ year lifespan - Durable construction for long-term use

- Customizable solutions - Tailored to your specific requirements

About Qingdao Ruly Steel Engineering Co., Ltd

We are a professional steel structure fabrication and engineering company located in Qingdao, China, specializing in design, R&D, manufacturing, and installation of prefabricated steel workshops, warehouses, logistics parks, and other light steel structures. Our 35,000 square meter facility has a monthly production capacity of over 1500 tons of steel components.

Certifications: ISO9001, ISO14001, GB/T28001, ASTM, SGS

Frequently Asked Questions

Are you a manufacturer or trading company?

We are a manufacturer with our own factory. You are welcome to visit our facility to inspect our production process and quality control measures.

Is your price competitive?

We offer the best price for equivalent quality and the best quality for equivalent price. Our goal is to reduce your costs while delivering premium products.

Do you provide installation services?

We provide detailed installation drawings and can send engineers or a complete installation team upon request.

What is your delivery time?

Standard delivery time to nearest Chinese seaport is 40 days after receiving deposit, depending on order quantity.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!