Anti Rust Fluorocarbon Coating Sandwich Panel Prefab Steel Structure Workshop Shed

Product Specifications

| Attribute |

Value |

| Application |

Steel Structure Warehouse |

| Type |

Steel Structure Warehouse |

| Raw steel material |

Q235B, Q355B, ASTM A36 |

| Service life |

50 Years |

| Wall and Roof |

Steel cladding sheet, Sandwich Panel |

| Surface treatment |

Painting/Galvanized |

| Working scope |

Design, Fabrication, Installation |

| Columns & Beams |

H-section steel |

| Standard |

AISC, ASTM, BS, DIN, GB, JIS |

| Origin |

Qingdao, China |

| Connection Type |

Bolt Connection |

| Parapet Wall |

As Requested |

Product Overview

Our Easy Installation Anti-Rust Fluorocarbon Coating Sandwich Panel Prefabricated Steel Structure Workshop Shed offers superior performance compared to traditional concrete structures. All components are factory-prefabricated for quick on-site assembly, resulting in excellent structural integrity, shorter construction time, and enhanced resistance to wind and earthquakes.

The lightweight steel construction reduces risks of collapse and injury during disasters. With minimal wet work required, our solution eliminates environmental pollution from dust and wastewater. The structures are easily relocatable, and steel components are fully recyclable for energy efficiency and environmental protection.

Technical Specifications

- Building Dimensions: Length 271m × Width 98m × Height 12.5m

- Color: Customizable to customer requirements

- Key Advantages:

- Cost-effective with attractive appearance

- High safety performance

- Easy assembly and disassembly

- Manufactured under ISO9001 quality control

- Installation guided by experienced engineers

- Environmentally friendly

Main Components

- Foundation: Cement and steel foundation bolts

- Main Frame: H-section steel columns and beams

- Material: Q235B, Q355B or custom materials

- Purlin: C or Z purlin (C120-C320, Z100-Z20)

- Bracing: X-type or other configurations using angle/round pipe

- Bolt: Plain bolt and high strength bolt

- Roof & Wall: Sandwich panel and color plate

- Door: Sliding or rolling door options

- Window: Aluminum alloy window

- Surface: Anti-rust painting or hot dip galvanized

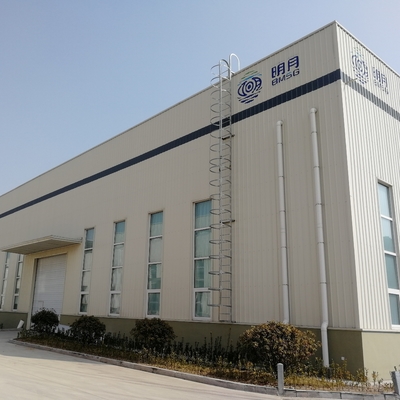

Our Manufacturing Facility

Our 35,000㎡ steel structure fabrication facility includes 20,000㎡ of workshop space equipped with:

- Light/heavy H steel production lines

- BOX production lines

- C/Z purlin production lines

- Advanced profiling steel sheet machines

- Plasma cutting machines

Installation Process

We provide detailed construction drawings prior to installation and can dispatch engineers for on-site guidance or complete the installation with our professional construction team.

Client Projects

Frequently Asked Questions

Are you a manufacture factory or trading company?

We are a manufacturing factory. You're welcome to visit our facility to see our quality control processes and professional operations firsthand.

Is your price competitive compared with other companies?

We offer the best price for equivalent quality and the best quality at comparable prices. We're committed to reducing your costs while ensuring you receive premium products.

Can you send engineers or whole team to install my project?

We provide detailed installation drawings at no cost. We can send engineers as installation supervisors or a complete installation team upon request.

Do you accept container loading inspection?

We welcome inspectors at any stage of production, including container loading.

Do you offer designing service for us?

Yes, we provide complete design solutions using AutoCAD, PKPM, MTS, 3D3S, Tarch, and Tekla Structures for complex industrial buildings.

What is the delivery time?

Delivery typically takes 40 days after deposit receipt, depending on order quantity.

How can you get a quotation for your projects?

Contact us via email, phone, WhatsApp, or Viber 24/7 for a response within 8 hours.

Our Advantages

- Professional design team for custom solutions

- Skilled fabrication team with advanced equipment

- Comprehensive one-stop service for complete projects

- Dedicated quality control team

- Reliable after-sales service and maintenance support

Request a Quote

Please provide the following information for an accurate quotation:

| 1 |

Location (where will it be built?) |

_____country, area |

| 2 |

Size: length*width*height |

_____mm*_____mm*_____mm |

| 3 |

Wind load (max. wind speed) |

_____kn/m2, _____km/h, _____m/s |

| 4 |

Snow load (max. snow height) |

_____kn/m2, _____mm |

| 5 |

Anti-earthquake requirements |

_____level |

| 6 |

Brickwall needed or not |

If yes, 1.2m high or 1.5m high |

| 7 |

Thermal insulation requirements |

EPS, fiberglass wool, rockwool, PU sandwich panels or metal sheets |

| 8 |

Door quantity & size |

_____units, _____(width)mm*_____(height)mm |

| 9 |

Window quantity & size |

_____units, _____(width)mm*_____(height)mm |

| 10 |

Crane needed or not |

If yes, _____units, max. lifting weight____tons; max. lifting height _____m |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!