Multi Storey Steel Frame Construction Steel Warehouse Pre Engineered Steel Structure

Product Attributes

| Attribute |

Value |

| Application |

Multi storey steel frame construction |

| Type |

Prefab Steel Frame Structure Buildings |

| Raw steel material |

Q235B, Q355B, ASTM A36 |

| Service life |

50 Years |

| Wall and Roof |

Rock wool |

| Working scope |

Design, Fabrication, Installation |

| Columns & Beams |

H-section steel |

| Standard |

AISC, ASTM, BS, DIN, GB, JIS |

Product Description

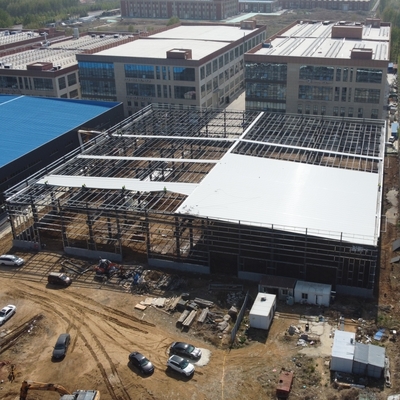

This multi-storey steel frame construction is a pre-engineered steel structure designed for warehouse and parking buildings. The five-storey steel frame consists of steel beams, columns, and trusses, offering superior stiffness, seismic performance, and rapid construction compared to traditional reinforced concrete structures.

Specification of Steel Structure Material

| Items |

Specification |

| Main Steel Frame - Column |

Q235, Q355 Welded H Section Steel |

| Main Steel Frame - Beam |

Q235, Q355 Welded H Section Steel |

| Secondary Frame - Purlin |

Q235 C and Z purlin |

| Secondary Frame - Knee brace |

Q235 Angle Steel |

| Secondary Frame - Tie Rod |

Q235 Circular Steel Pipe |

| Secondary Frame - Brace |

Q235 Round Bar |

| Vertical and Horizontal Support |

Q235 Angle Steel, Round Bar or Steel Pipe |

| Maintenance system - Roof Panel |

EPS Sandwich Panel / Glass Fiber Sandwich Panel / Rock Wool Sandwich Panel / Pu Sandwich Panel / Steel Sheet |

| Maintenance system - Wall Panel |

Sandwich Panel / Corrugated Steel Sheet |

| Accessories - Window |

Aluminium Alloy Window / PVC Window / Sandwich Panel Window |

| Accessories - Door |

Sliding Sandwich Panel Door / Rolling Metal Door / Personal Door |

| Accessories - Rainspout |

PVC |

| Live load on Roof |

120kg/Sqm (Color steel panel surrounded) |

| Wind Resistance Grade |

12 Grades |

| Earthquake-resistance |

8 Grades |

| Structure Usage |

Up to 50 years |

| Temperature |

Suitable temperature: -50°C to +50°C |

| Certification |

CE, SGS, ISO9001:2008, ISO14001:2004 |

| Finishing Options |

Vast array of colors and textures available |

| Paint Options |

Alkyd painting, two primary painting, two finish painting (gray paint, red paint, white paint, epoxy zinc etc.) Or Galvanized |

Our Steel Structure Fabrication Factory

Our 35,000㎡ fabrication facility includes 20,000㎡ of workshop space equipped with three light/heavy H steel production lines, BOX production lines, C/Z purlin production lines, and advanced machinery including plasma cutting machines.

Our Services

We provide comprehensive design, fabrication, and installation services for customized steel structures including warehouses, workshops, hangars, commercial buildings, and industrial facilities.

Frequently Asked Questions

Are you factory or trading company?

We are factory.

What kinds of structural steel do you produce?

Steel columns, variable cross-section columns, cross columns, H beams, arc-shape H beams, two cross-section beams, variable cross-section beams, box beams, tie beams, sectioned beams, arc-shape beams, castellated beams, etc.

Where to use your structural steel?

Steel structure buildings, warehouse, workshop, factory, office building, shopping mall, hospital, apartment, etc.

What equipment do you have for manufacturing?

CNC cutting machine, H-Beam Auto Assembly Machine, Auto submerged arc welding machine, Flange Straightening Machine, Hydraulic Brake Type Plate, Shearing Machine, Numerical Control Cutting Machine, Three Torches Straightline Cutting Machine, Magnetic drill machine, Intelligent&Manual Welder, Air Compressor, Sandblasting Machine, etc.

What welding standard do you use during processing?

GB, JIS, ASTM.

What method do you use for packing?

Steel pallet on the bottom, wood among each layer and cable for fastening, or as per your requirements.

For any other question or further discussion, please send us inquiry or email!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!